|

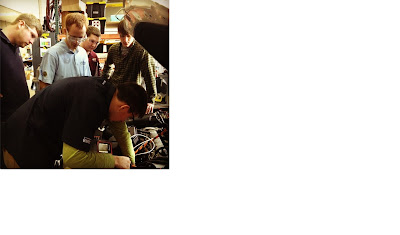

| Andrew with Lynn Gantt working on the engine test stand. |

Andrew Karpin was an electrical subteam member of HEVT during Year 3 of EcoCAR: The NeXt Challenge. He is now an engine calibration engineer at Robert Bosch LLC and was hired through one of the EcoCAR sponsor socials.

“Advanced vehicle technology competitions exposed me to the tools and processes of the auto industry, which has lead me to excel in my profession,” Andrew said. He is responsible for a wide variety of engine calibration components, but he primarily focuses on engine start calibration.

Andrew joined the team in the final year of the EcoCAR: The NeXt Challenge competition for his senior design project. “I discovered HEVT through Virginia Tech course request, and being a gear head, I naturally seemed interested in the project,” Andrew said.

Although there were some challenges and stressful moments throughout the year, the experience and skills he learned were well worth it. “My favorite moment on the team was when we won first place in EcoCAR in Washington D.C.,” Andrew said. “Who doesn’t like being on the winning team?”

“I think it’s great that HEVT is getting more and more students involved,” Andrew said. “If anyone wants to have a job in the auto industry, HEVT gives the necessary tools to excel.” He thinks very highly of the program, not only in the engineering aspect, but of the communication team as well. “I do like the fact that outreach and vehicle updates have improved over the last two years.”

Andrew just bought a house in the Michigan metro area and is making it very engineer friendly. “I’m currently outfitting my pole barn vehicle lift, and have several projects already waiting in the wings,” Andrew said. We wish him the very best in his automotive engineering career.

.jpg) |

| Andrew (3rd from the left) with other HEVT members. |